Ask any of our customers the biggest benefit to Right Weigh scales and they’ll tell you it’s the savings in time and money. They change everything about the vehicle weight management process—removing unnecessary side-trips to check a load, eliminating the risk of expensive tickets and delays for non-compliance, and saving thousands per truck.

When we asked Vladi, he was enthusiastic about these benefits:

“I’m happy using Right Weigh because not only do I save money from the scales, but they also save me time…Let’s say you’re overweight and you gotta drive 50 miles to scale it. Now you’ve driven overweight 100 extra miles just to make sure you’re legal on the road…

You don’t need to drive overweight [at all] if you can fix an incorrect weight before leaving the customer. Right Weigh gives you the confidence not to stop for extra measurements.”

When asked what other benefits he’s gotten from Right Weigh scales, Vladi says safety and driver satisfaction are also high up his list.

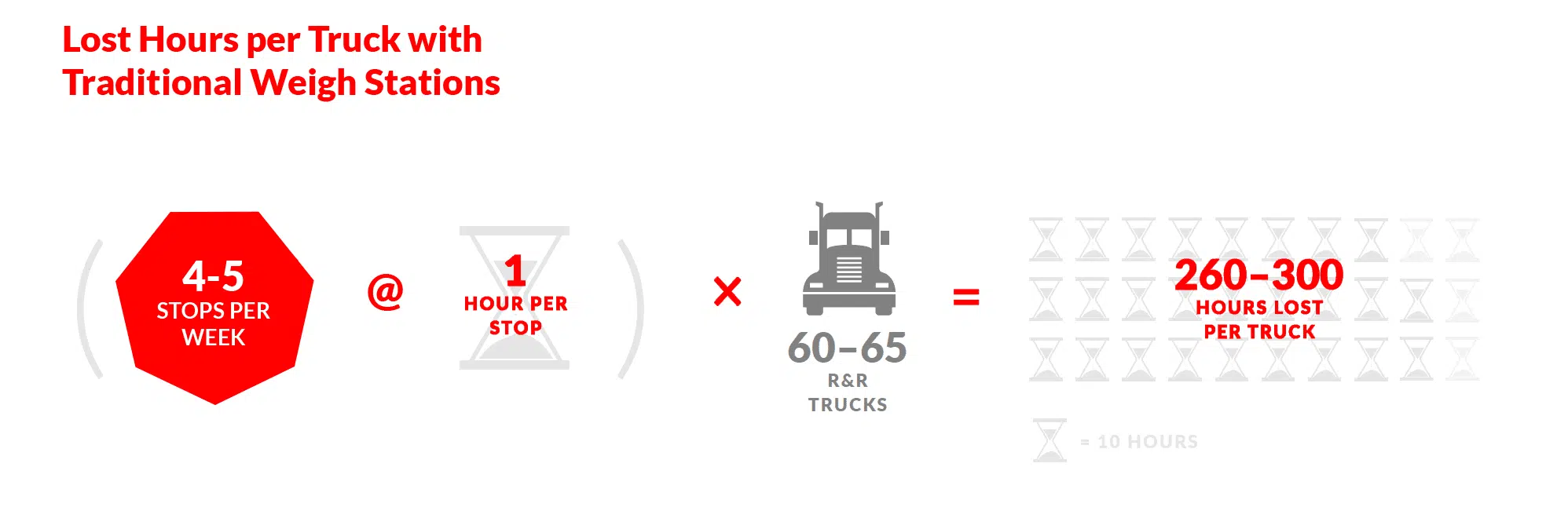

After all, the less time drivers are stopping to scale their loads, the less time they’re on the road, the more time they can spend with their families, and the less likely they are to drive tired or have to stop for an additional overnight to comply with maximum driving hour limits.

At the end of the day, Vladi says more people should be using Right Weigh scales:

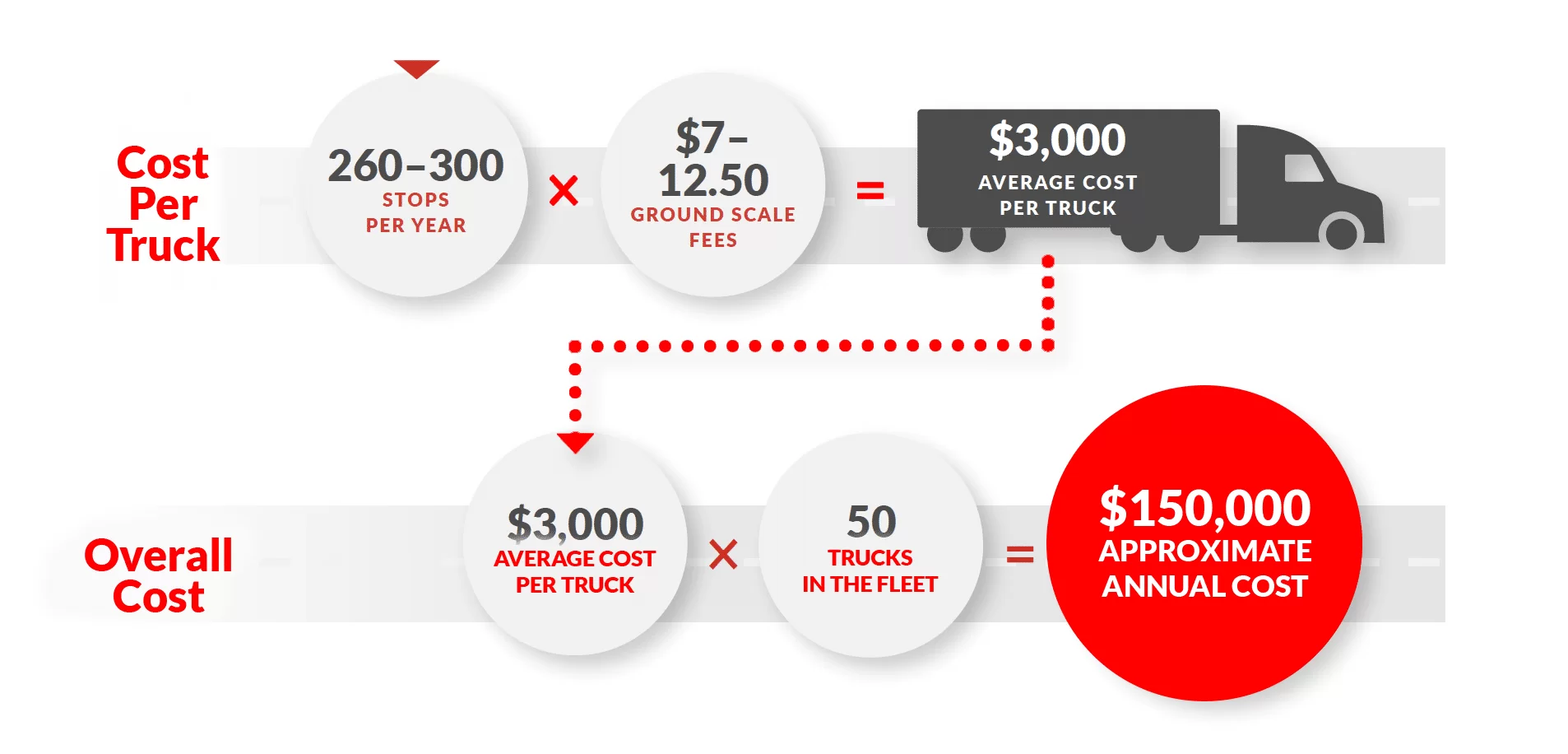

“The cost and time savings are more than enough reason to use these scales. It’s an easy calculation: it’s saving me thousands every year…If I knew about Right Weigh 10 years ago, I’d have been using them the whole time.”